Documentation

Complete and updated service and product documentation available for viewing and download. Select a category to begin your search.

InfoTeleves 75 (june)

- General Information: Televes wins the Red Dot Award 2025: a new international recognition for our design and innovation

- Our people: Ángel García Manager of Televes Global Services (TGS)

- Televes Corporation: The engineer who commissioned the first RAS machine

- Product news: New Overlight Series set top boxes

- FAQs: How do I splice two sections of optical fiber?

- Televes facilities: Azuri Peninsula residential complex (Lagos, Nigeria)

- Televes in the world: Mobile World Congress 2025, Eltefa 2025, NAB Show, Televes Mobile Unit

- Training: Importance of sheath materials for telecommunication cables

- Announcement: AVANT 12

General Information

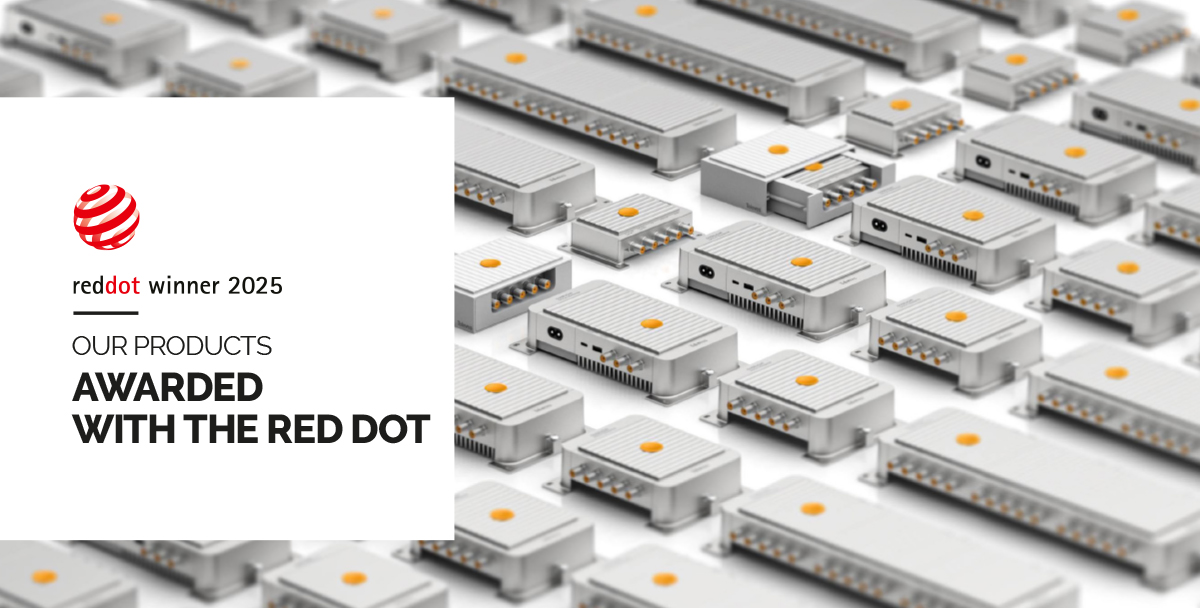

Televes wins the Red Dot Award 2025: a new international recognition for our design and innovation

The accolades keep coming. In this case, we are especially proud to receive the prestigious Red Dot Award: Product Design 2025, one of the most prominent international awards in the field of product design.

In this edition, we received the coveted Red Dot seal in the Communication Techology category for our TV Distribution Family: a range of products that represents the latest in signal distribution technology with a functional and advanced design.

These products were selected from thousands of international applications by a panel of experts. The reason? Quality, innovation, and industrial excellence, with a concept of modularity and design language represented by its distinctive emblem: an orange heart that captures the history of the brand and projects it into the future.

This new recognition not only reflects our commitment to aesthetics, but to something much more important: creating useful, efficient, and future-proof technological solutions. And, as always, with Televes’ trademark quality and reliability.

Exhibition at the world's largest contemporary design museum

The winning products will be part of the “Design on Stage” exhibition at the Red Dot Design Museum in Essen (Germany), located in a unique space: the Zollverein complex, a UNESCO World Heritage Site. They will also be included in the Red Dot Yearbook 2025, an internationally renowned publication.

An internationally recognized track record of excellence

This Red Dot Award 2025 adds to a growing list of awards that demonstrate our commitment to innovation and design. In recent months, Televes has also received the Good Design award in the USA, the German Design award in Germany and the European Product Design award in Europe, consolidating itself as a leading brand in the technological/industrial field worldwide. These awards highlight the value of our solutions, designed to improve people's lives and the efficiency of the environments where they are installed.

Our family of products for TV distribution was chosen for its quality, innovation, and excellence in industrial design.

Our people

Ángel García Manager of Televes Global Services (TGS)

In-house design and manufacturing are key to Televes, which, supported by a true vocation for service, strengthens customer trust.

The consolidation of the TGS service and support area has been key to Televes' growth in recent years. We have the pleasure of talking to one of its leaders to learn a little more about the real value provided to our customers

How would you describe your work at Televes?

My priority is to offer customized after-sales services for the different Televes business areas, ensuring close, effective service from pre-configuration to technical support. My role involves defining and implementing project management methodologies, standardizing processes, optimizing communication, and ensuring service quality in diverse, complex contexts. Although challenging, it represents a constant opportunity for improvement and learning, enhanced by a professional, collaborative, and committed team that shares common goals.

How long have you been with the company? How would you describe your career so far?

With almost 20 years of experience, I see my career as a continuous learning process, marked by adaptation to new technologies, constant improvement of the service, and team management in a collaborative and results-oriented environment, with the motivation intact to keep growing.

What is the most satisfying part of your job and what is the most difficult?

The most satisfying thing about my work at Televes is having contributed to the growth of the services area, creating solutions for market needs and consolidating a solid offer; in addition, supporting the development of talented and committed people is a great source of motivation.

In a changing and challenging environment, marked by technological and geopolitical uncertainty, the resilience and strength of a solid team are essential to face difficult situations and keep moving forward.

What do you feel the key values are in the company?

In-house design and manufacturing are key to Televes, but I believe that what strengthens our customers’ trust is to support them with a true vocation for service, which is reflected in friendly, professional service from all areas, which positions us as a reliable and committed partner.

Televes Corporation

The engineer who commissioned the first RAS machine

In the history of Televes, there are names that will be remembered forever. One such name is Antonio Gándara, an industrial master with the soul of an engineer, whose talent and character marked one of the key moments in the company's development: the commissioning of the RAS machine in 1965.

His history at Televes began with Ricardo Bescansa, president and founder, with whom he shared a practical and ambitious view of technology. A collaboration was born where Ricardo's ideas flowed and took shape in Antonio's expert hands. This relationship of trust became a professional friendship and, above all, one of the pillars of Televes' first great technological challenge.

Those who worked with him remember Antonio for his direct, demanding manner, but also something much more important: he was brilliant. He did not need big speeches or unsupported theories. He was able to demonstrate with deeds, with lathes, with milling cutters, with millimetric adjustments that turned an idea into a reality. He was a workshop man, but with an engineer's mind.

Televes' first major strategic move was the decision to manufacture our own aluminum antennas. This was a visionary decision that went against majority opinion, given the supply issues with this material in the 1960s. There would be an added challenge: the purchase of the RAS machine, a piece of German equipment designed to manufacture aluminum tube from strip, and induction weld it with radio frequency. This was a risky exposure for the young company, which invested 1,950,715 pesetas in acquiring the machinery in 1965—almost half of its annual turnover—for a technology that simply did not work.

When the delays stacked up and the facility was still not operating, Ricardo Bescansa decided to travel to Germany. And he did not hesitate to ask Antonio and Mr. Herbert, a German living in Spain and hired by Bescansa, to accompany him.

When they arrived in the city of Sindelfingen, near the Mercedes Benz headquarters, they found that the machine, designed by RAS for tube forming and AEG Elotherm for induction brazing, was assembled in a wooden storehouse outside the factory because it was too large, and surrounded by engineers who had no idea why it wasn’t working. They were stuck, overwhelmed by the challenge. The 12 mm tube didn't work, the 26 mm tube failed, and the German engineers didn't know how to solve it.

With the calculations made by Mr. Bescansa and with the support of Mr. Reihart, engineer and founder of RAS, Antonio Gándara and the rest of the technicians analyzed, disassembled, adjusted and modified the machine. He made changes to the production lines and induction coil. He did so by interpreting detailed information in German and the electrical schematics of the induction system. They calculated the values of the coil over and over again, reducing the length of the coil, to see if it was within the tolerances marked on the schematic. The final proposal to reduce the coil was not approved by AEG, but it was approved and authorized by Mr. Reihart.

And so 12 mm aluminum tube was welded with RF, according to the Germans, for the first time in history. Engineer Reihart would later confess to Bescansa that “that young Spanish engineer was very good.”

And so Antonio Gándara was. And not just because of that day in Germany. His legacy encompasses much more: structures, shipbuilding, even aeronautics. But it was at Televes where he left an indelible mark: On that RAS machine, which is still in operation today, modernized thanks to ISF engineering, but with the same spirit as then: that of solving an impossible problem, with talent and audacity.

Remembering him today is much more than paying tribute. It is to recognize that behind every advance, every innovation, there are people who made it possible. Antonio Gándara was one of those people. And his history is part of the soul of Televes.

Product news

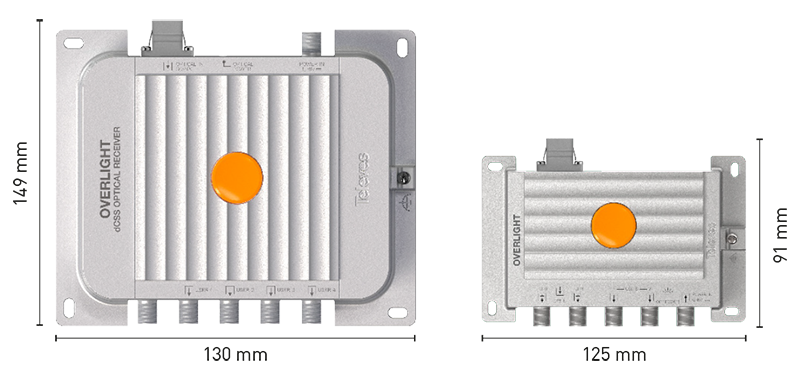

New Overlight Series set top boxes

An international award-winning modular design

The Overlight Series continues to evolve with the launch of the new generation of optical receivers, compatible with multiple receiving technologies and satellite operators. Thanks to its optimized electronic performance and low losses, it is possible to reduce the number of amplifier devices required and simplify deployment in collective installations, while preserving end-to-end signal quality.

These devices have a completely renewed look and feel, winning four prestigious international awards for design and modularity. Its manufacture in zamak creates an optimal balance between robustness and lightness, with excellent shielding against interference.

The basic principle of the Overlight Series remains intact, with two main elements in the installation: the optical transmitter, which receives the RF signals from the antennas and converts them into an optical signal for fiber transmission, and the optical receivers, which receive this signal and convert it back into RF for reception at the end devices.

Thanks to the high output power of the transmitters and the low losses of the fiber, Overlight makes it possible to carry the TV signal over long distances and distribute it to up to 64 users completely passively or 512 by using an optical amplifier. These characteristics give it great flexibility to tackle projects of different scale and complexity. The multiple wavelengths available allow for multiplexing the optical signals from several transmitters to distribute up to 4 satellites and DTT over a single fiber, and additionally integrate GPON.

This range of set top boxes covers all three receiving technologies: Quattro, Quad and dCSS, making it possible to reach all types of installations:

The Quad model (ref. 237650) allows direct connection of up to 4 set top boxes, and is key for FTTH and FTTR.

The Quattro model (ref. 237640) is designed for direct connection to a multiswitcher, facilitating distribution in a collective installation, for FTTB or even for FTTR with several satellites.

The dCSS compatible line includes models with 2 and 4 outputs (refs. 23762x and 23763x respectively), which are specifically configured for the UBs (User Bands) typical of the countries and satellite operators that have implemented this technology.

With this new generation of optical receivers, we reaffirm our commitment to innovation in television distribution, offering an advanced, efficient, and future-proof solution.

FAQs

How do I splice two sections of optical fiber?

Various methods can be used to join two sections of optical fiber, although the most common methods are mechanical splicing and fusion splicing. A mechanical splicer is an acceptable option for occasional use. However, even though the tool is affordable, this advantage has to be weighed against the cost of the splice materials, which is 10 times higher than the cost of a fusion splice. If a poor result is achieved, the splice material cannot be reused, and specific optical equipment must also be available just to detect the problem. For all these reasons, fusion splicing is the best option for professionals who regularly work with optical fiber infrastructure. A fusion splicer measures optical losses after the fusion splice is completed. This provides secure information that the fusion has been performed correctly, and if it has not, the splice can be repeated at no extra cost. This method greatly reduces uncertainty and the possibility of flaws in the optical fiber cable.

In the case of specific applications where the lambdas are defined, such as for certifying telecommunications infrastructure under Spain’s ICT2 regulations, it is possible to find devices that automatically take all of the optical measurements. This saves time and effort for the installer because the same process does not have to be repeated for each lambda.

Finally, a professional fusion splicer presents a fast, simple, and reliable fusion process as long as the steps are performed in the appropriate order.

If you want to learn more about these steps, you can watch our tutorial video:

watch the videoTeleves facilities

Azuri Peninsula residential complex (Lagos, Nigeria)

The Azuri Peninsula is an ambitious luxury residential project located in the exclusive Marina district of Eko Atlantic City in Lagos, Nigeria. Developed by Eko Development and designed by internationally renowned Gensler Architects, this complex seeks to redefine high-end urban living in West Africa.

Televes has been involved from the initial stages of the project.

A highly complex system was designed, aligned with the magnitude of the development, in which our solutions offer comprehensive connectivity and television services using GPON technology. This infrastructure takes full advantage of the capabilities of GPON networks to meet the high demand for services in a luxury residential complex, overcoming the technical challenges associated with the large vertical and horizontal distances between towers.

Start-up represented a significant challenge; however, thanks to impeccable teamwork with the integrators, the implementation has been a success.

Televes in the world

Mobile World Congress 2025, Eltefa 2025, NAB Show, Televes Mobile Unit

Mobile World Congress 2025 (Barcelona, Catalunya) March 3 - 6

Our shared presence with GSertel served to present the latest solutions for connectivity in buildings and urban environments, where we featured the 5G Router, which improves IoT in environments with poor coverage, and our consolidated DEZA range for optical transport networks with DWDM technologies.

Eltefa 2025 (Stuttgart, Alemania) March 25 - 27

We saw a large number of visitors interested in fiber optic technologies and CoaxData. Our experts from the German subsidiary Jacob Dag, Markus Gronbach, Marc Peter, Tino Setzmüller and Dieter Haag provided personalized advice on our latest innovations.

NAB Show (Las Vegas, EE.UU.) April 5 - 9

Sharing a booth with our sister companies Gsertel and TRedess, we presented the latest innovations in TV broadcasting and distribution.

We featured OTA solutions compatible with NextGen TV, the AvantX headend, H30 portable meters with ATSC 3.0 support and SmartKom, nicknamed the “rotor killer.” As always, we deployed the full range of our state-of-the-art DTT antennas: Ellipse, Evoca and DiNova, optimized for maximum OTA performance.

Televes Mobile Unit (Italy) March 25 - April 15

With 15 stops in Lazio, Sardinia, Campania and Triveneto. This fifth edition was carried out with the emblematic Televes truck, conditioned to provide installers a direct experience with the brand and an up close and personal experience with TV/SAT and DATACOM products and the new GPON and FTTH technologies.

Now we are on our way to Germany!!

Training

Importance of sheath materials for telecommunication cables

Keys to choosing the right one for each installation

The choice of sheath material for cables such as coaxial, data or even fiber optic, is a critical factor that directly affects their durability and safety, and therefore their performance over time. The sheaths protect the core of the cable, where the information travels, from external aggressions, but not all of them are designed to withstand the same conditions. Below, we analyze the most common materials according to their application:

PVC sheath:

the usual solution for conventional indoor installations

Polyvinyl chloride (PVC) is a common choice for indoor applications, although the current CPR (Construction Products Regulation) of each country must be taken into account. This material offers good mechanical resistance, although its behavior with respect to fire and the emission of toxic gases limits its use in crowded spaces. It is not suitable for outdoor installations as prolonged exposure to solar radiation or moisture can quickly deteriorate it.

LSFH sheath:

safety in public spaces and in specific outdoor applications

LSFH sheaths (Low Smoke Free Halogen, also known as LSZH or LS0H), are designed to minimize the emission of toxic and corrosive fumes in case of fire. This makes them the best choice for indoor use in high occupancy environments such as hospitals, shopping malls, airports or public buildings in general. In addition, if these sheaths have been treated with additives resistant to ultraviolet (UV) rays, they can also be used in short exterior installations, such as downspouts on facades. It should be noted that, at present, the legislation in some countries expressly requires the use of this material in specific high-occupancy scenarios, as is the case of common telecommunications infrastructures in Spain.

PE sheath:

Outdoor use and underground wiring

Polyethylene (PE) sheaths are common in outdoor installations due to their excellent resistance to moisture, UV rays and atmospheric agents. However, it is important to note that they are not intended to be buried directly in contact with the ground. Their use in underground wiring is permitted, provided that the cable is placed inside a suitable resistant conduit, which insulates it from direct contact with the ground.

When greater protection is required, the use of cables with integrated Petro-Gel can make all the difference. Petro-Gel is a water-repellent mineral compound with a high melting point that is incorporated as an internal filler, preventing moisture from entering and protecting the integrity of the cable even in very demanding environments. Although this combination allows for more reliable performance in outdoor installations, it is still not sufficient to classify the cable as suitable for direct burial in the ground, as they often lack other essential features such as rodent protection or double mechanical shielding.

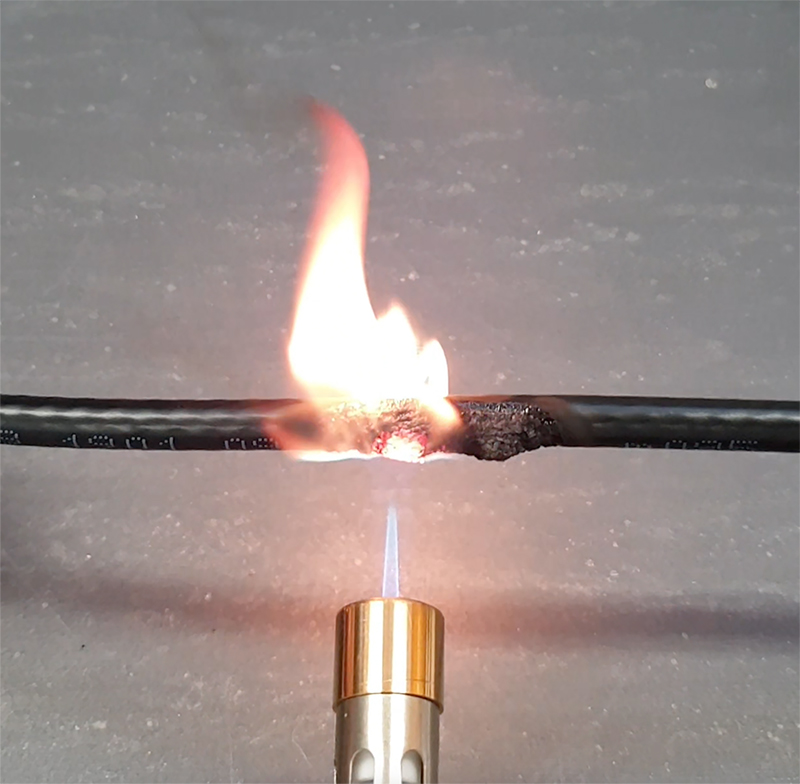

Fire test with a PVC cable, where we see that it is more flammable and emits fumes.

Fire test with an LSFH cable, where we see that it does not emit smoke and minimizes the spread of flames.

Common indoors.

Not recommended in public or high-occupancy buildings.

Not recommended for outdoor use.

Common indoors.

Recommended in public or high-occupancy buildings.

Outdoor use, if it has UV resistance and only in short stretches of low exposure.

Common outdoors.

Use in underground wiring (preferably with Petro-Gel).

Not recommended for burial in direct contact with the ground.

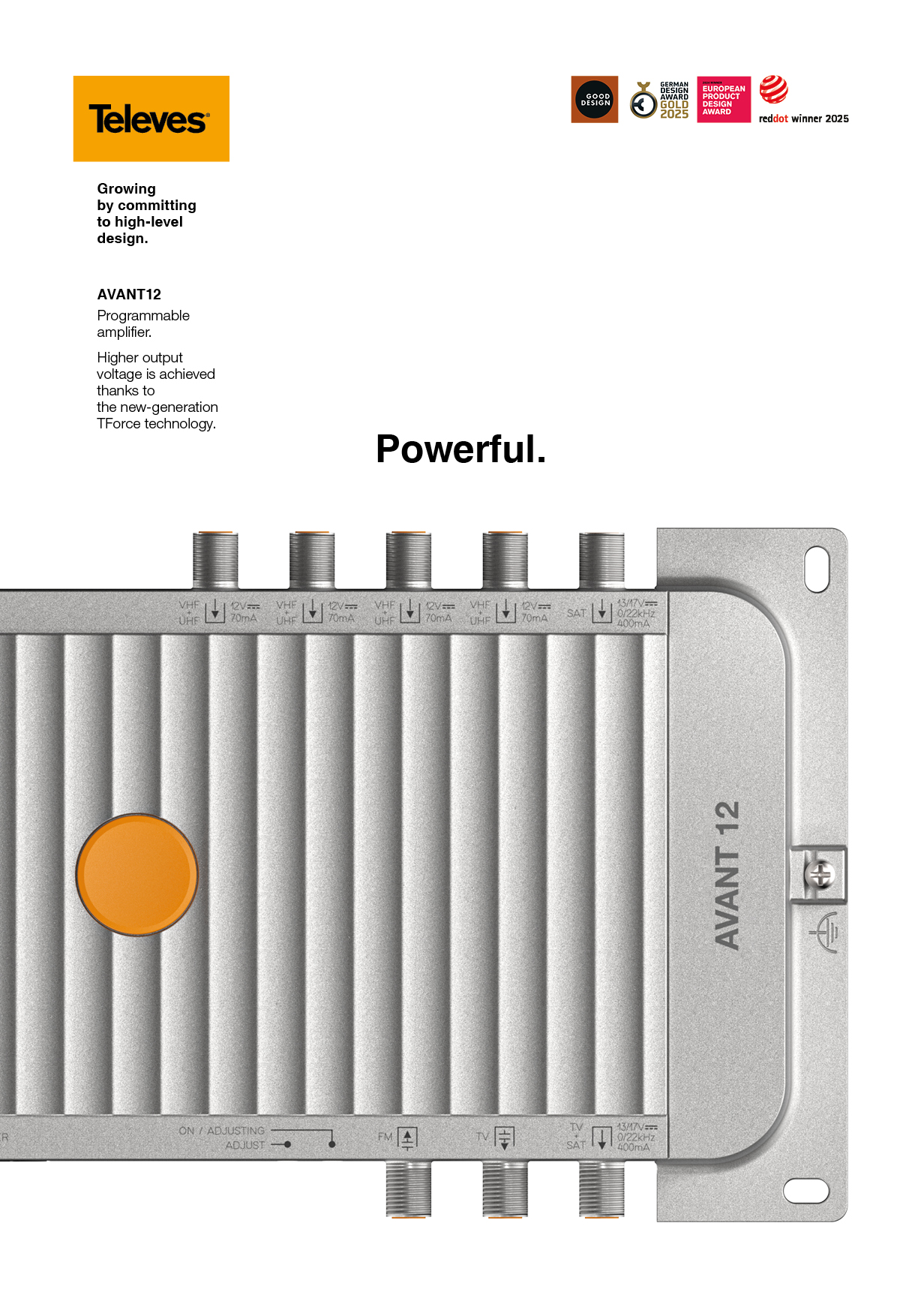

Announcement

AVANT 12