Documentation

Complete and updated service and product documentation available for viewing and download. Select a category to begin your search.

InfoTeleves63(June)

- General Information: Diversification brings growth: Televes Corporation opens a new workplace

- Our people: Julio Viqueira. Head of Production Maintenance

- Televes Corporation: Gsertel and Televes lead the technological change in the United States

- Product news: H30D+ field meter with DOCSIS 3.1

- Ideas: Control your TV remotely without remote control

- FAQs: Do I need to clean optical connectors that remain unused?

- Televes facilities: Battersea Power Station (London, United Kingdom)

- Televes in the world: ANGACOM | NAB Show | Evolving Connectivy by CAI

- Training: Optical fiber cable splicing with an arc splicer

- Announcement: FLEX | High-power modular lighting

General Information

Diversification brings growth: Televes Corporation opens a new workplace

Televes’ business areas keep growing steadily, even if the challenges that we are currently facing are considerable. On top of that, the ever-evolving industry we operate in has been also experiencing notable disruptions due to the global pandemic – which has been among us for two years already.

Despite this, we continue to work to balance the well-established traditional market of communication infrastructures. Supported by our acquired technological knowledge, our future depends on the efficiencies of all of our business areas.

Our consolidated areas specialized in the fields of Hospitality, Professional LED Lighting and Optical Transport are showing a constant growth, to the point that we have been forced to rearrange our work groups to exploit synergies efficiently.

As a result, in early may, Televes Corporation opened a new workplace called Galileo – located in Santiago de Compostela (Galicia). The departments specializing in business, management, design, software and technical support will be backed by these areas to optimize resource organization and to boost work dynamics, while promoting cross-function expertise.

We are very excited about this milestone in our organizational growth. We really hope that this new corporate center boosts the talent of our colleagues from the areas of Hospitality, Professional LED Lighting and Optical Transport. Let’s follow the example of our traditional business area – TV Distribution – and build loyalty for more than 60 years.

The new workplace Galileo will boost cross-function expertise in the development of solutions and products of the business areas in the fields of Hospitality, Professional LED lighting, Optical Transport, as well as the Global Services support areas and software development.

Our people

Julio Viqueira. Head of Production Maintenance

It is always highly satisfying to solve breakdowns or complex processes, knowing that I provide good service to production

We wanted to take advantage of the important milestone of the recent renewal of the first MMIC surface mount component assembly machine for the latest model on the market, to talk to one of the main architects in the execution of the migration.

What is your job at Televes?

I am the head of the group that maintains the robotic manufacturing lines and SMD circuit and assembly machines. I actively participate in troubleshooting and commissioning of new machinery, a complex issue when speaking of MMIC technologies, where we are pioneers, and the machines we receive are among the first to leave Siplace.

How long have you been with the company? Could you describe your career?

I joined Televes Robotica in February 1990 as a technician, where the first robotic lines were already being set up. I alternated with the manufacture of machinery and tooling and the repair of SMD machines, especially the HF3, the third to leave Germany. Given the company's vision of the future I was always being trained in the latest generations of SMD assembly machinery and lately MMIC.

What is the most satisfying part of your job?

It is highly satisfying to solve breakdowns or complex processes, knowing that I provide good service to production.

With the MMIC start-up, there have been countless hours of testing, adjustments and calibrations, in coordination with other departments. They had to be done with no disruptions of production. So what initially took a full day of installation, configuration and calibration was quickly reduced to just two hours of processing time.

What about the most difficult?

It usually happens on days when you work non-stop, you put everything you have into it, but things get frustrating and you don't get the expected results. In the case of the complex migration to MMIC assembly processes, all the people involved gave their all, and ultimately attained a very important milestone for the company. After the hard challenge, you also get the pride of a job well done, but soon you have to start again because Televes is in constant evolution in manufacturing.

What do you feel the key values are in the company?

Undoubtedly, working in a company that not only has excellent professionals, but also invests every year in being at the forefront of technology. I truly believe we can do anything we set our minds to.

Televes Corporation

Gsertel and Televes lead the technological change in the United States

Broadcast Operators search for key partners that can swiftly develop professional tools to manage and control their DTT ATSC 3.0 roll-out projects. Sinclair has found in Gsertel the perfect ally for their portable field spectrum analyzers.

Gsertel is the test and measurement subsidiary of Televes Corporation, providing dedicated technical support in the ATSC 3.0 roll-out in the United States through the Televes US subsidiary.

The Gsertel Hexylon field spectrum analyzer has been chosen by Sinclair for its versatility and real-time precision on any measurement required. The Gsertel engineering team's flexibility allows for new features to be developed promptly as the ATSC 3.0 roll-out generates new needs.

Hexylon is intended for professional users requiring advanced features and precise measurement accuracy, analysis and diagnostics of television and radio signals. Hexylon is not just a portable meter with a touch screen, but rather a new way of testing network signals, developed on the basis of a multi-touch screen. The content becomes the user interface and everything flows in an intuitive way using gestural commands.

The future of ATSC 3.0 is already here and it is very clear that Gsertel and Televes will play a starring role in this scenario.

Operators appreciate the dedicated and exquisite local support and knowledge we provide, letting our advanced technology take care of the rest. Good things are ahead for broadcast networks in the US and Gsertel and Televes expect to be a key partner in the ATSC 3.0 and SFN roll-out process.

Product news

H30D+ field meter with DOCSIS 3.1

Maximum functionality, even in CATV cable systemsCable infrastructures are still evolving and adapting to the current technological changes to deliver broadband services, such as IP services to end users.

The new H30D+ field meter adapts to installers’ daily needs to offer the best results in the installation, monitoring and maintenance of CATV networks . Its advanced functionalities make it possible to work with QAM and analogue channels, as well as with DVB-T/T2 or ATSC 1.0/3.0 terrestrial television standards, all without having to change equipment.

The H30D+ model also stands out for its compatibility with cutting-edge DOCSIS 3.1 networks, as it has the capacity to carry out all the measurements of the OFDM DOCSIS channel and the network’s upload and download speeds.

Thanks to its one-of-a-kind capability to remotely control and measure, it helps solve intermittent problems that are hard to find in cable systems, as well as carrying out specific tasks such as:

- Scanning every existing analogue and digital channel in real time to determine the system’s overall frequency response, displaying an intuitive colour code that shows whether the signal levels comply or do not comply with the cable system specifications.

- Demodulating and analysing IPTV Unicast and Multicast flows, presenting all the information in each of the services and thus completing the measurements in RF.

- Wireless remote control of the meter via your smartphone or tablet, thanks to the exclusive Multiscreen system typical of meters from the H30 series.

- Emulating a modem so that the H30D+ can be used to provide connection from the DOCSIS network to other devices through its Ethernet port.

This range of meters, designed for use on cable networks, includes H30+, a simple tool that enables installers to carry out basic installation, maintenance and troubleshooting tasks in networks with DVB-C and analogue channels.

Ideas

Control your TV remotely without remote control

The fields of use of our products often expand beyond the main use for which they were conceived thanks to the feedback we receive from our partners and the new applications that appear on the market. Thus, although the main application of our interactive TV system is still guest entertainment in the hotel room, it is now possible to remotely control the TVs without the need for a remote control and from a central control console.

This is very useful for TVs that are in common areas of hotels or other venues where you want to control centrally and remotely what content is displayed on screen.

Another area of application would be sports bars where there are several screens showing different live sporting events, and where using a remote control to control the TVs can be a problem, especially because: if the TVs are of the same brand the remote can act on all of them at the same time and not only on the TV on which you want to act. On the other hand, it also requires the remote controls to be located and it is not possible to perform a centralized remote control of the contents.

With our in-house developed STB Nemesis V2, this situation is solved, since it provides the system with the capacity for remote management of screens either locally or remotely.

FAQs

Do I need to clean optical connectors that remain unused?

Yes, it is mandatory in order to ensure people’s safety, and advisable so that the optical installation will remain in good condition over time. Protective caps are normally already included and fitted as standard on optical equipment and serve a dual purpose:

- Protecting people: the radiation emitted by the laser (infrared 1300 - 11000 nm) can cause damage or burns to the human eye. Therefore, it is mandatory to keep the fiber connectors capped, even during the installation of the equipment.

- Protecting the fiber : if the ends of the connectors are left in the air, they can become dirty, causing greater losses in the link. In addition, if the particles are abrasive, which is common in construction sites, the friction generated when trying to clean the connector may cause irreparable damage to the connector, requiring it to be replaced by a new one.

In addition, a dirty connector is not only a danger to itself, but may end up transferring dirt or damaging the fiber surface of other connectors or adapters with which it comes in contact.

Thus, maintaining good protection and cleaning practices with optical connections can avoid a lot of problems in the future.

Televes facilities

Battersea Power Station (London, United Kingdom)

Using the FIBER4SAT solution, four satellites and DTT have been distributed over a single optical fiber to a group of apartments and commercial premises in the surroundings of the historic and emblematic Battersea building in London.

Among other advantages over other solutions, FIBER4SAT simplifies optical distribution while minimizing power consumption.

The project included the deployment of the headend, which includes the reception of the 4 satellites, one of them from the operator SKY, their DWDM multiplexing (key in the choice of the FIBER4SAT solution) and optical amplification using an EDFA with 16 outputs, each one with the capacity to give signal (illuminate in slang) to 256 apartments.

Optical set top boxes and Multiswitches are installed in each apartment to provide signal to 16 sockets.

The FIBER4SAT solution is perfectly adapted to the deployment phases of the project. In a first phase, 254 apartments have been illuminated and in a second phase, 737 apartments have been illuminated, with the expectation that approximately 300 more will be illuminated in the near future and another 200 within two years.

Televes in the world

ANGACOM | NAB Show | Evolving Connectivy by CAI

ANGACOM (Cologne, Germany) May 10-12

Nobody completes the integral solutions in telecom infrastructures for buildings and homes as well as Televes. At the AC32 booth we were able to share thematic blocks in areas such as Multiplay over F.O., Hospitality solutions, fiber or coax distribution, even high efficiency and low latency Optical Transport networks.

NAB Show (Las Vegas, Nevada, USA) April 23-27

Corporate presence at its best. Finally NAB Show resumes the physical presence and Televes, TRedess and Gsertel had their own stands to share their news with a market technologically focused on the Repack of the radio spectrum and the evolution to ATSC 3.0. This market is beginning to play an important role.

Evolving Connectivy by CAI (Birmingham, United Kingdom) March 17

Training

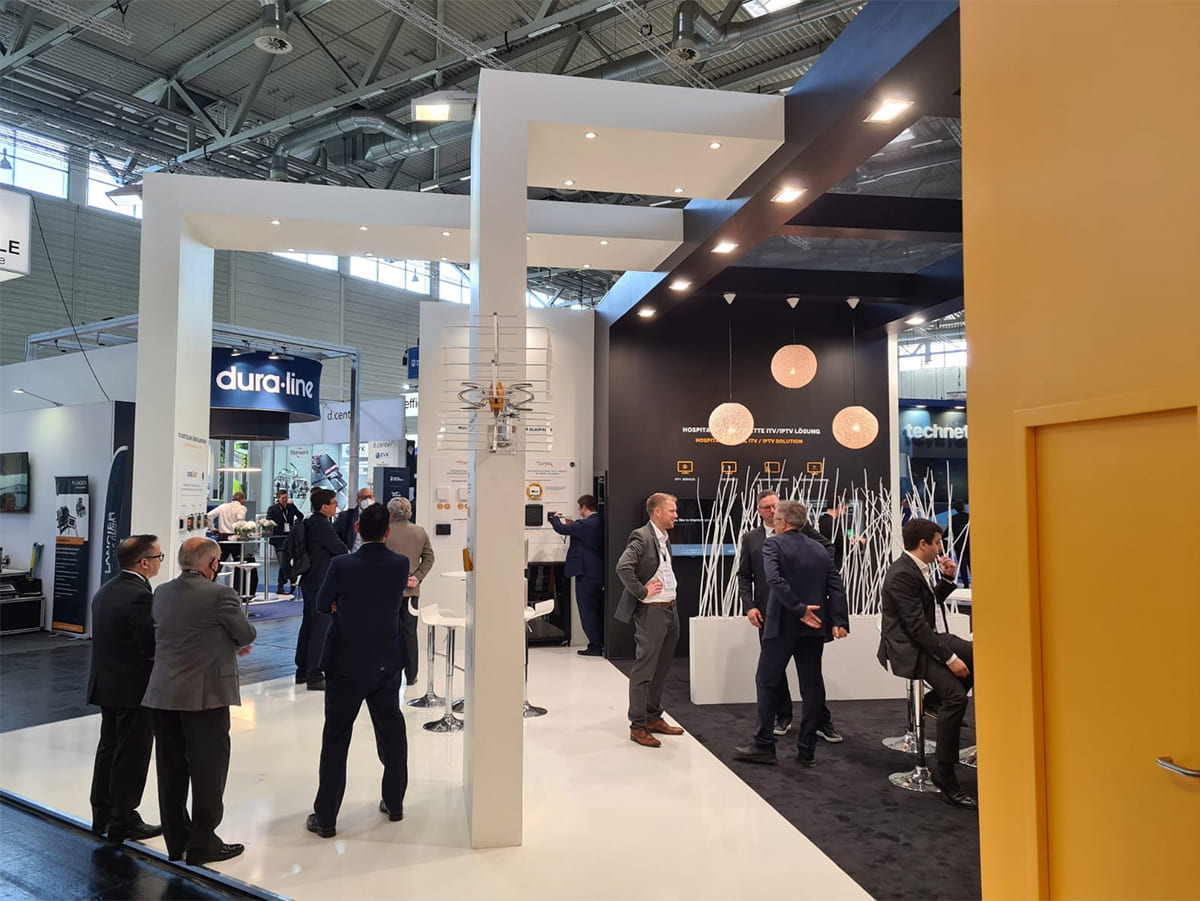

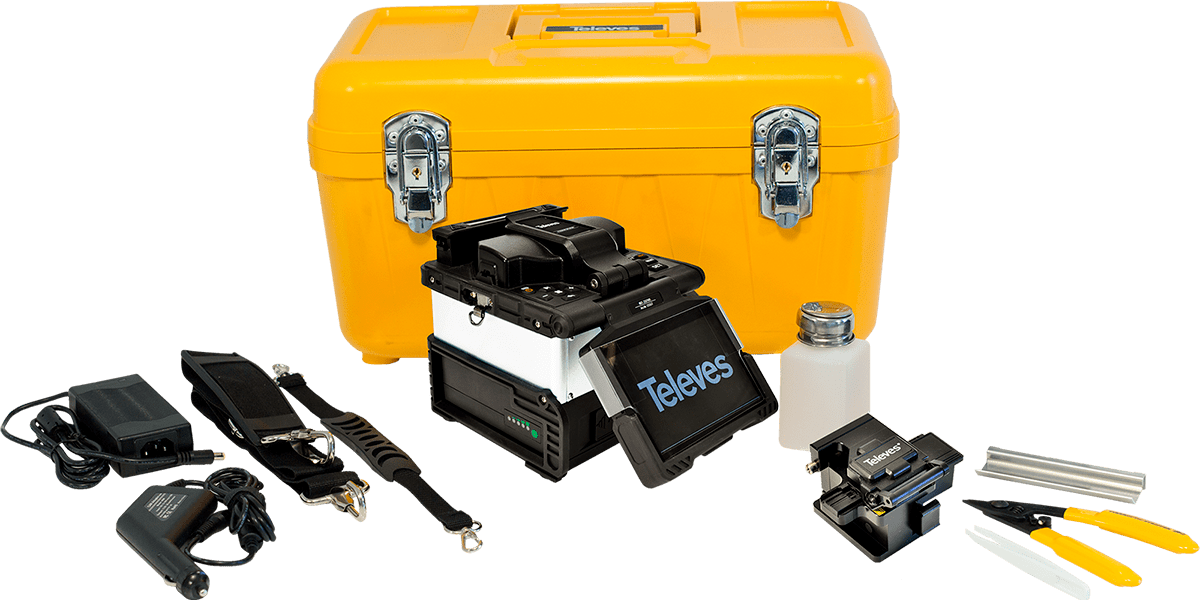

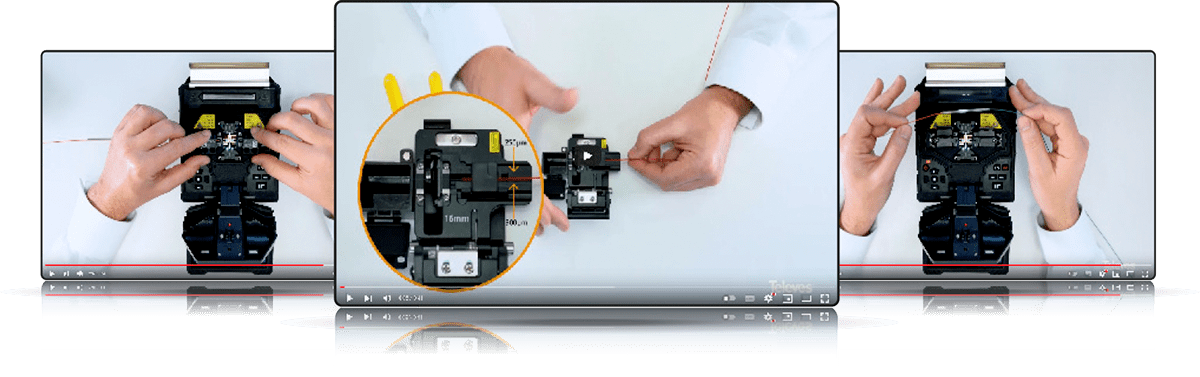

Optical fiber cable splicing with an arc splicer

How can I carry out a complete splicing process?There are basically two methods for joining two sections of optical fiber: mechanical splicing and fusion splicing. A mechanical spliceris an appealing option for occasional use. However, for professionals who regularly work with fiber infrastructures, a fusion splicer is undoubtedly the best choice.

The first thing to do to make a splice is to prepare the optical fiber cable; insert the heat-shrinkable cannula through the fiber and then proceed with the stripping. The usual stripping size should be between 3 and 4 cm in length. Once the fiber cover is stripped off, remove the first protection of 900 microns and then the second one of 250 microns. Once this process is completed, the next step is to clean the fiber (125 microns, and we recommend the use of the cleaning kit ref. 232710) and then proceed with the cut. For this purpose, place the fiber protective sleeve 16 mm from the cutting point and then close the cutter. Once the cutter is opened, remove the excess fiber from the collector and extract the optical fiber, which is now ready to be spliced. The same process is repeated with the second fiber, the fiber to be spliced.

Once both fibers are ready, they are passed to the splicer. Insert the first optical fiber on the V-groove and lock it. Follow the same procedure with the second fiber and then close the cover so that the splicing process can begin automatically. After this process, the screen shows the estimated attenuation losses (usually around 0.02dB) and the cover can be opened by removing the two spliced fibers. Before positioning the fiber in the oven insert the protective cannula over the zone that has just been spliced. The baking will be done automatically once the fiber is placed on it and the oven LED will turn off and beep when the process is finished. After this, just remove the fiber and place it in the upper zone of the splicer, the cooling zone.

For more details on each of these steps, watch our video tutorial:

en.televes.com/232105Announcement

FLEX | High-power modular lighting